Turbo Machinery Parts Inspection

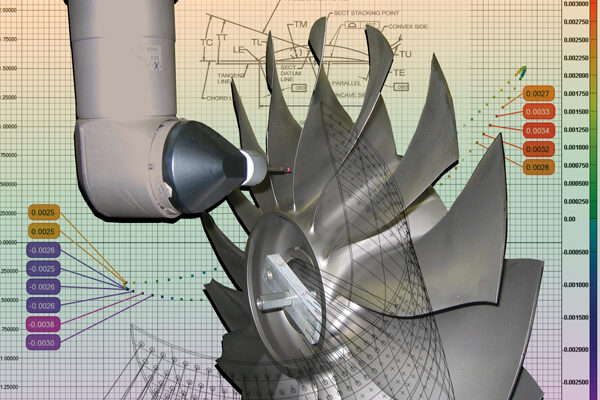

We specialize in the inspection of turbo machinery parts, including impellers, turbine wheels, compressor wheels, stator blades, blisks, rotors and various cast and formed housings. These are usually defined by CAD geometry, with some critical dimensions called-out on the part drawing. Our software tools include Metrolog XG, Zeiss Calypso and Polyworks. Together with Zeiss, Faro and Mitutoyo hardware, we have all the tools necessary to gather data and present results in a clear, concise and complete report. We can work under very strict accuracy requirements in our environmentally controlled lab with calibration records traceable to NIST.

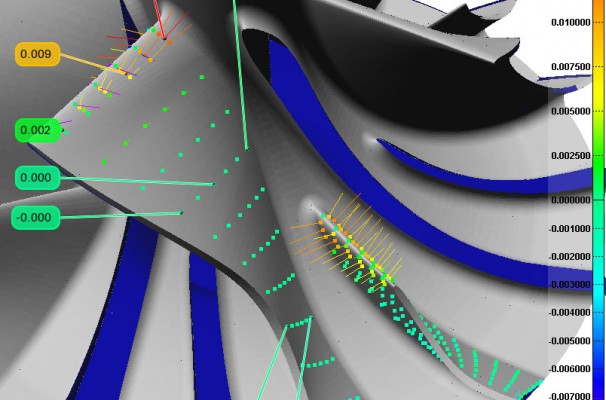

This compressor wheel was measured on the Zeiss CMM. Measurement data were exported to Polyworks, where the “colormap” report was generated. This shows a direct comparison between the customer CAD file and measured data.

Here’s a link to a video showing inspection of a bladed disk (blisk).